AutoPlan

Preliminary Planning of Complex Production Systems

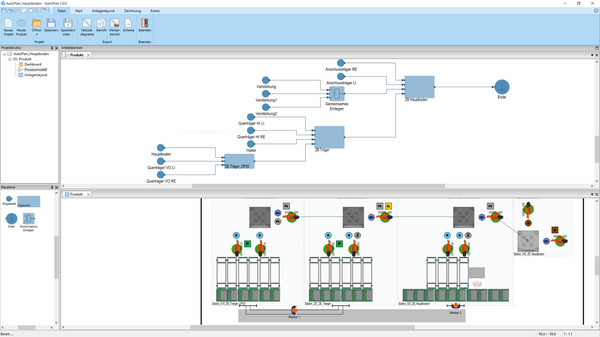

AutoPlan significantly simplifies the process of preliminary system planning. At no additional effort, this software solution enables an estimation of the structure and behavior of a production plant by means of simple simulations and intelligent evaluation procedures. Production processes are modeled graphically in the form of process chains (process model) and requirements for the production system are defined. The resulting process steps are automatically transferred into production systems. Different designs can be projected and compared, and it is also possible to create a rough physical plant layout.

AutoPlan integrates seamlessly into existing PLM systems, obtains its input parameters from them and outputs the results to the PLM system for further planning. AutoPlan thus closes the automation gap in production planning and is a valuable tool for digitization in industry.

Considered Characteristics of Production Systems

- Systems with clock cycles and linked systems

- Configurable joining processes such as welding, bonding, gluing etc.

- Stationary and geostable joining processes

- Tool changes and double tooling

- Fixtures, rotary tables

- Material provisions, handling processes and 7th axes

- Manual processes, worker utilization

At a Glance

- Automatical generation of production system layout and cycle time diagrams

- Quick cost estimation

- Customizable rule set and resource library

- Minimum resource cost for a given cycle time (SALBP optimization)

- Simulation of plant behavior

Advantages

- Rough planning with just a few clocks

- Comparison of planning alternatives

- Quick and easy re-planning

- Reduced planning effort

- Decreased costs