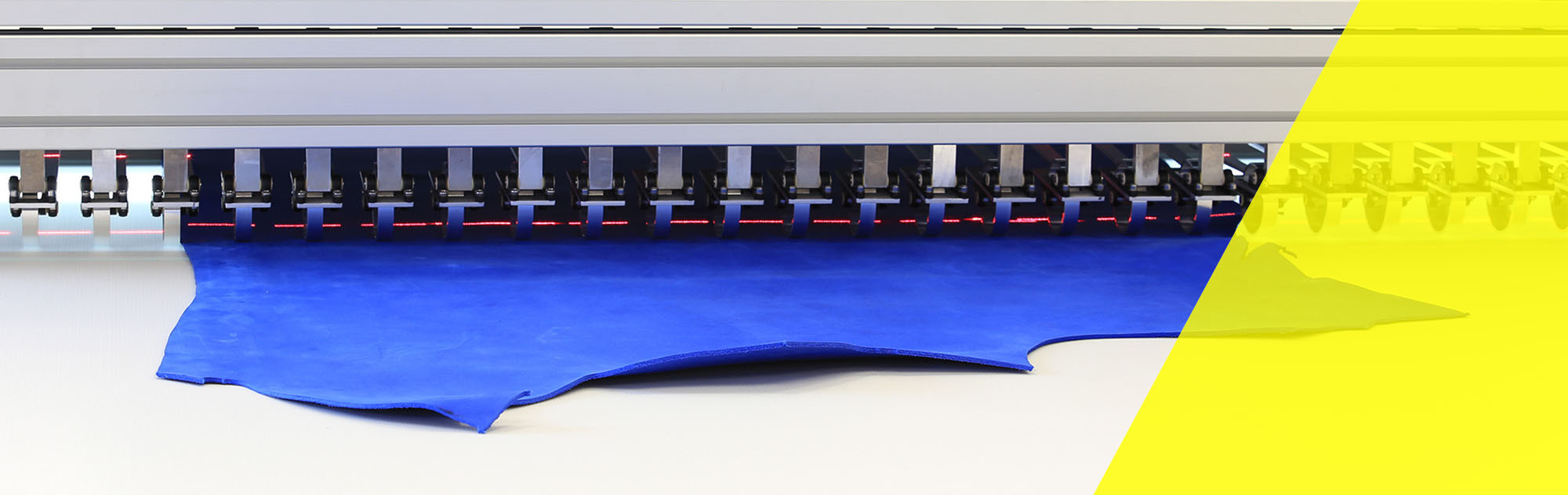

LQScan 3018

Leather measuring machine for area and thickness measurement

The LQScan leather measuring machine enables a simultaneous and efficient full-area measurement of surface and thickness of leather (and further non-transparent materials). The achieved accuracy of the surface measurement is significantly higher than reached with norm EN ISO 11646 (leather: surface measurement).

Features

- All-in-one system for leather measurement

- Including a storing installation (conveying technique for stapling the leather after measuring)

- High-precision measurement: accuracy of 25 μm in the range of 0,5 to 4,0 mm

- Continuous measurement process, several belt speeds available

- Optomechanical „scanning“ of thickness and outline with new camera and laser technique

- Determination of parameters relevant to quality and calculation for set tolerance bands

- Up to 4000 m² natural leather per shift

More details

| Measured objects | up to 3 m x 1,8 m x 5 mm (L x W x H) depending on model |

| Accuracy of measurement | 25 μm in the range of 0,5 to 4,0 mm |

| Measurement time | ≤ 20 sec. |

| Capacity | up to 4000 m² real leather per shift |

- Leather in a run-through process, the throughput speeds is adjustable

- Optomechanical „scanning“ of thickness and contour with new camera and laser technique

- Calculation of parameters relevant to the quality and calculation for pre-set tolerance bands

- Data storage in custom SAP environment

- Customized machine configuration: 1,60 m working height

- Signal when tolerances are exceeded

- Database access

- Label printing

| Type | Material width | Dimensions (L x W x H) |

| LQScan1809 | up to 900 mm | approx. 4 m x 1 m x 2 m |

| LQScan3018 | up to 1,800 mm | approx. 7 m x 2 m x 2 m |

| LQScanPro3018 | up to 1,800 mm | approx. 11 m x 2 m x 2 m (incl. automatic stacking) |

| LQScan3036 | up to 3,600 mm | approx. 7 m x 4 m x 2 m |